Most recent News & Articles

Breaking barriers: Banca Widiba's quest for gender equality in finance

Banca Widiba in Italy takes the issue of gender equality very seriously. In fact, its recent study on the subject provides an excellent overview of the situation in Italy. Francesca Marchelli, Director of Communications at Banca Widiba, spoke to Qorus' Boris Plantier about the subject.

Chubb to acquire Healthy Paws, a leading pet insurance provider

Chubb, the global insurance giant, has announced its definitive agreement to acquire Healthy Paws, a U.S.-based pet insurance provider, from...

Driving innovation in e-commerce payments: a conversation with mBank's award-winning leaders

Polish bank mBank won bronze in the Operational Efficiency category at the Qorus Reinvention Awards – Europe 2024 for ‘Conversion-Boosting...

eToro expands proxy voting feature to all stocks on its platform

eToro, the trading and investment platform, has extended its proxy voting feature to include all stocks listed on its platform,...

ABN AMRO doubles help with banking advisers to support digitalization

To achieve this, the bank is increasing the number of Help with Banking advisers to more than 200, effectively doubling...

CLV: Gaming insights are helping banks pinpoint key long-term customers

At an online event hosted by Qorus Digital Reinvention Community and marketing firm Numberly, Zachery Anderson, NatWest’s Chief Data and...

OCBC introduces program to aid women entrepreneurs

The programme offers tailored financing solutions, educational workshops, and networking and mentorship opportunities.

Most recent Studies & Reports

Driving forces: The interplay of financial services and the EV sector

The financial services sector and the electric vehicle (EV) sector are two dynamic realms undergoing a significant transformation in today's...

A bancassurance breakthrough: Nurturing SME relationships through customized insurance products

In this paper, we outline the opportunity bancassurance presents to banks, as well as the key considerations that should be...

Innovation Radar: Reinvention Awards Europe winners 2024

Discover the most innovative projects from banks and insurance companies in Europe.

Unleashing SME banking potential with embedded finance: Simplifying financial services to create unprecedented convenience for SMEs

In this paper, we will unravel the key challenges that banks need to address to not only navigate the upcoming...

Latest innovations

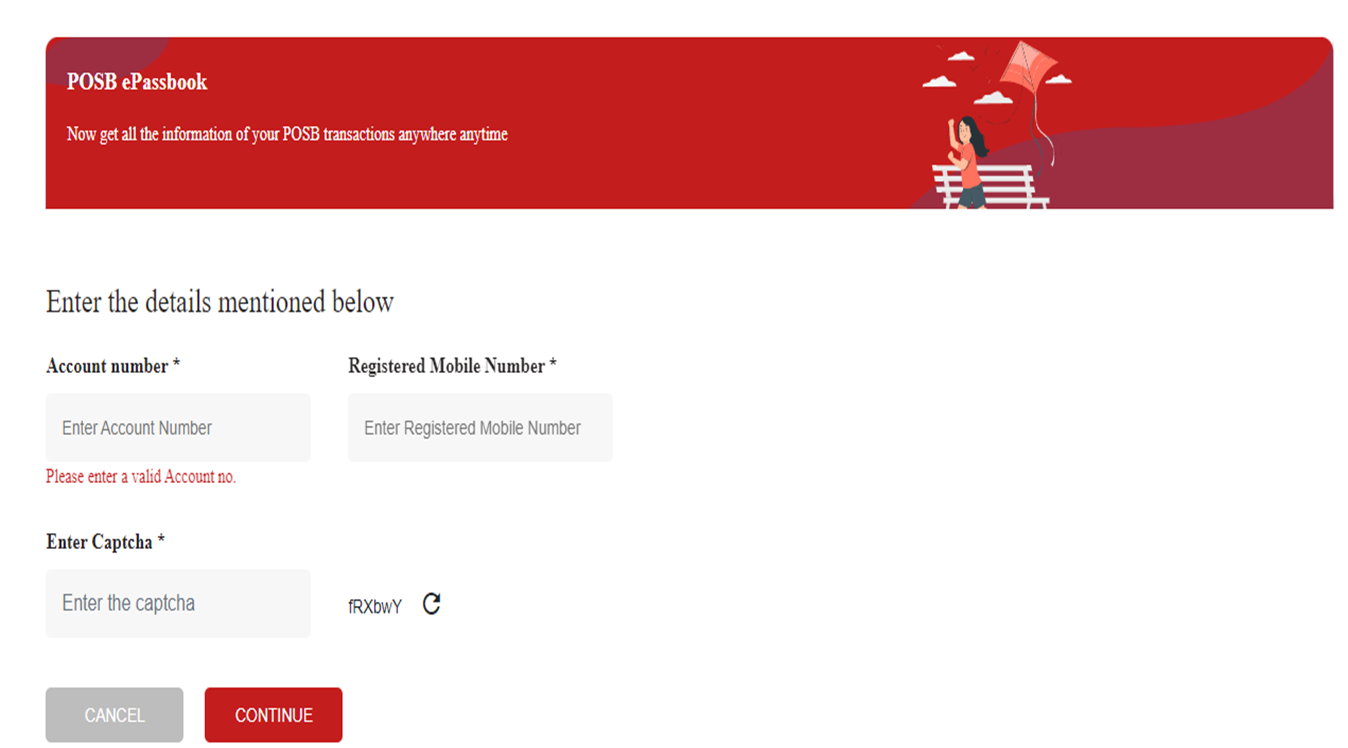

E-Passbook functionality for DOP services

->Customer can visit IPPB Webpage : https://www.ippbonline.com/web/ippb/dop-product-payment ->Customer can Login using Registered Mobile Number and authentication through OTP. -> After...

New Ireland Assurance Advisor Portal

Executive Summary: The challenge we set for ourselves was ambitious and required a complete transformation of our ways of working,...

New Ireland Assurance Customer & Broker Portal

The challenge we set for ourselves was ambitious and required a complete reimagining of the customer experience. Traditionally financial advisors,...

AIA One--Reimagining the sales agent experience at AIA Thailand

At AIA, we are leveraging Technology, Digital and Analytics (TDA) across our business as we transform into a customer-centric, digital...

Join the Qorus

Today, Qorus is a catalyst for reinvention for our financial services members by helping them to go further, be faster and work together.

Forthcoming events

Cybersecurity: The role of the banks and insurance

Examine symbiotic relationships between financial institutions and embedded cybersecurity insurance, emphasizing collaborative efforts against digital risks and cyber threats. This session organized with our partner Allianz Partners, will explore the complexities of cybersecurity within the financial services industry and discuss effective cyber risk management practices. Invited experts will examine how...

Technology-driven sustainable synergy: Maximizing the Impact of green finance and IT solutions

Discover the powerful synergy between green finance and IT solutions, driving global sustainability through innovative collaborations. Position your organization as a leader in building a greener future by leveraging this dynamic alliance to contribute to a sustainable world.

Reinvent Forum Lisbon

Reinvent Forum Lisbon - is dedicated to the digital transformation influencing the insurance sector. Our event brings together industry leaders, experts, and innovators to delve into the latest trends and strategies for enhancing customer satisfaction through innovative digital endeavors. Attendees can expect profound insights into the evolving landscape of insurance.

Electric vehicle charging

Future position of insurance in mobility will be shaped by ongoing technological advancements, changing consumer behavior, and evolving regulatory frameworks. One of the key roles of insurance in mobility will be to provide coverage for new and emerging risks associated with the use of new technologies, such as autonomous vehicles...

Climate change and insurance gap

Climate change intensifies the insurance gap, driving a surge in extreme weather events and economic losses. Join our online event to collaborate on building a more resilient future in the face of climate change.

We help banks and insurers to reinvent themselves to thrive.

Further

Further

We curate inspiring and innovative projects, technology and ideas so individuals, teams and organisations can collectively create the future of financial services.

Faster

Faster

We’re a catalyst for reinvention, improving revenue generation, creating efficiencies, redefining customer experiences and forming profitable relationships.

Together

Together

We're a neutral space where members unite to share, learn and collaborate, thinking freely to solve problems through an ecosystem of unique, specialist communities.

.png)